Düsen- & Material-Finder

Wähle dein Setup – erhalte eine Empfehlung und passende Produkte. Wenn du nur ein Düsensystem auswählst, werden alle kompatiblen Düsen angezeigt.

Passende Düsen

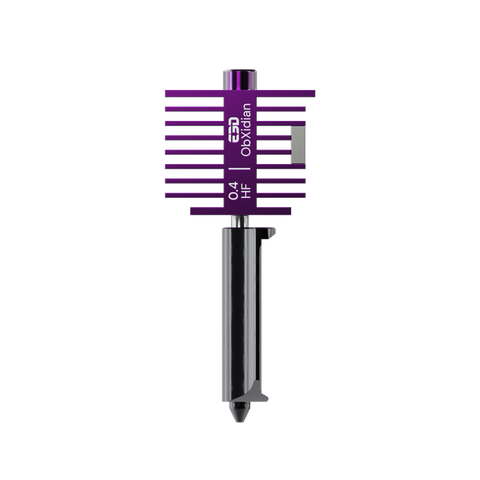

E3D V6 ObXidian Nozzle

Micro Swiss coated nozzle for Creality K1, K1 Max, CR-M4

Elegoo Orangestorm Giga Düsen Set 20 Stk

Creality 3D K1 / K1 Max Nozzle Kit

Micro Swiss FlowTech Nozzle – Brass-coated, wear-resistant for K1/K1 Max

E3D DiamondBack HotEnd for Bambu Lab X1E

Phaetus Conch Hotend Plus for Bambu Lab X1 / X1C – 0.4 mm (with Heater & Thermistor)

E3D-ObXidian hotend with high flow for Bambu Lab P1 series, fully assembled

E3D DiamondBack HotEnd for Bambu Lab P1 Series

Phaetus EndCoat K1C Nozzle

Nozzle set for Flashforge AD5X (4 pieces)

FlowTech CHT High Flow Nozzle for 3D Printing

MK10 hardened steel nozzle 0.2 mm - 1 piece

PrimaCreator Raise3D Pro2 Hardened Steel Nozzle

E3D High Flow Brass Unicorn Nozzle for Creality K1C, K1 Max & Ender 3 V3

E3D High Flow ObXidian Nozzle for Prusa Nextruder (MK4 & XL)

Flashforge Adventurer 5M/5M Pro stainless steel nozzle 0.4 mm

PrimaCreator Raise3D Pro2 Brass Nozzle 0.4 mm

E3D High Flow ObXidian K2 Plus Nozzle

Elegoo OrangeStorm Giga 0.6mm Düse

E3D ObXiDian 500 Revo Nozzle

E3D High Flow ObXiDian 500 Revo Nozzle

E3D ObXidian High Flow HotEnd for Bambu Lab A1 / A1 Mini

E3D DiamondBack HotEnd for Bambu Lab A1 / A1 Mini

E3D Revo™ High Flow X Hotside Kit – ObXidian Nozzles, abrasion-resistant & high flow

Raise3D Pro2 Brass Nozzle 0.8 mm - 1 Piece

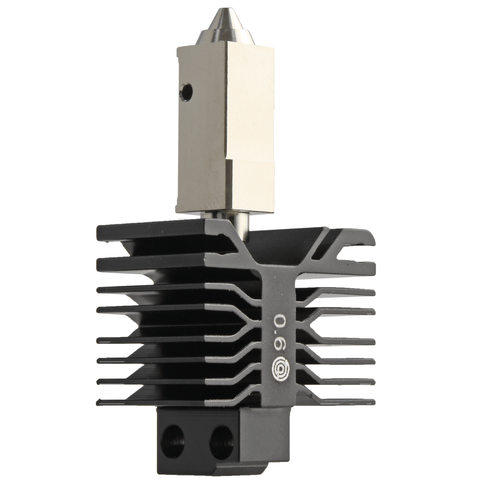

Phaetus Dragonfly HIC HF Nozzle 0.6 mm Hardened Steel – Integrated M6 Welded Construction

Phaetus xCreality SiC K2 Plus Nozzle

RepRap M6 Brass Nozzle 3mm - 0.4mm - 1 Piece

Micro Swiss HighFlow 1.75 Nozzle for 3D Printers

Phaetus Volcano Compatible Tungsten Carbide Nozzle 0.8 mm

Phaetus Volcano Compatible Tungsten Carbide Nozzle 0.6 mm - 1 Piece

E3D Revo High Flow High Temp Abrasive Nozzles – up to 500 °C, wear-resistant

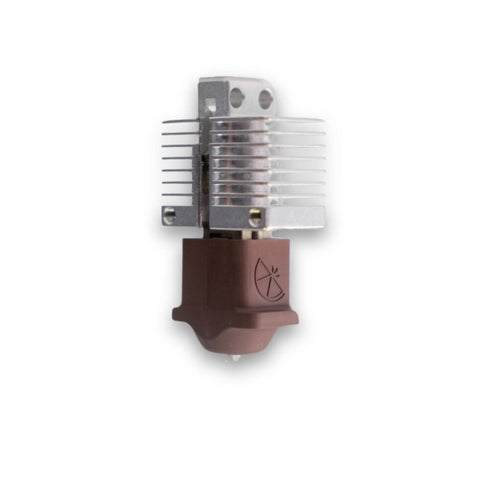

PrimaCreator Hotend H for Bambu Lab A-Series – 0.4 mm / 1.75 mm

Slice Engineering Mako™ Hotend with Electronics for Bambu Lab P1/P1P - GammaMaster Nozzle

E3D DiamondBack Hotend Bambu Lab P1 Series

PrimaCreator Bambulab A Series Hotend H 0.6mm 1.75mm

Slice Engineering Mako Hotend for Bambu Lab X1E - GammaMaster FIN Nozzle

Slice Engineering Mako Hotend for Bambu Lab X1/X1C – with Bondtech CHT Fin Nozzle

Phaetus Conch Hotend Bambulab X1/P1, 0.4mm

PrimaCreator Bambulab Hotend H 0.8mm for 1.75mm Filament

PrimaCreator Bambulab Hotend 0.4mm for X & P Series

PrimaCreator Bambulab Hotend H 0.6mm 1.75mm

Phaetus Conch Hotend Plus Bambulab X1/X1C 0.6mm with heater and thermistor

Micro Swiss FlowTech Hotend for Bambu Lab X1/X1C – Brass CHT High Flow

E3D High Flow HTA HotEnd Bambu Lab X1E

PrimaCreator Bambulab Hotend H 0.4mm for 1.75mm Filament

PrimaCreator Bambulab Hotend 0.25mm for X & P Series

PrimaCreator Bambulab Hotend 0.6mm for 1.75mm Filament

3D Printer Nozzles – precise extrusion for every material

The choice of the right 3D printer nozzle determines print quality, speed, and material usage. Whether standard brass nozzle, hardened steel nozzle for abrasive filaments, or high-flow variants for fast prints – here you will find the suitable solution.

What types of nozzles are there?

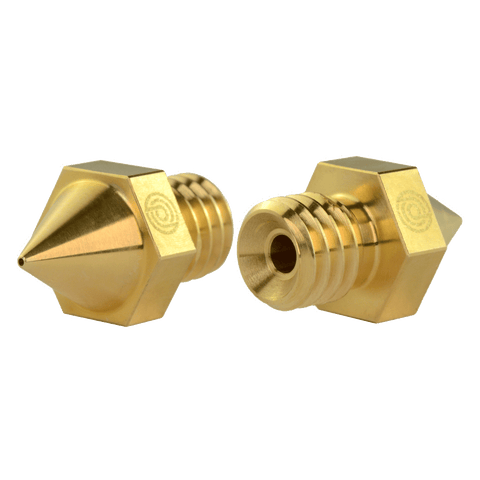

- Brass: standard for PLA, PETG, and TPU – very good heat conduction, ideal for all-round use.

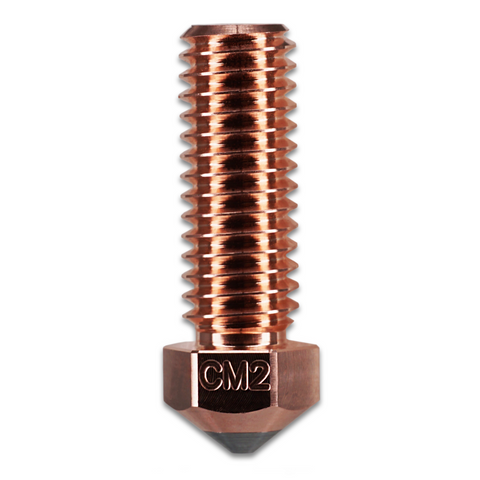

- Plated Copper: nickel-plated copper nozzles for even heat and high temperatures up to approx. 500 °C.

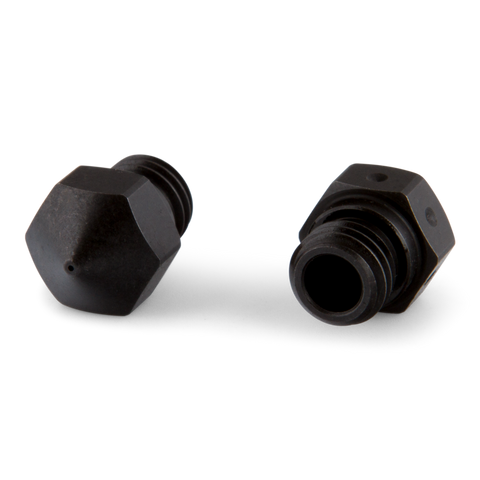

- Hardened Steel: wear-resistant for CF, glass, or glow filaments, usable up to approx. 450 °C.

- Ruby & Special Nozzles: highest durability, precise bores even with very abrasive materials.

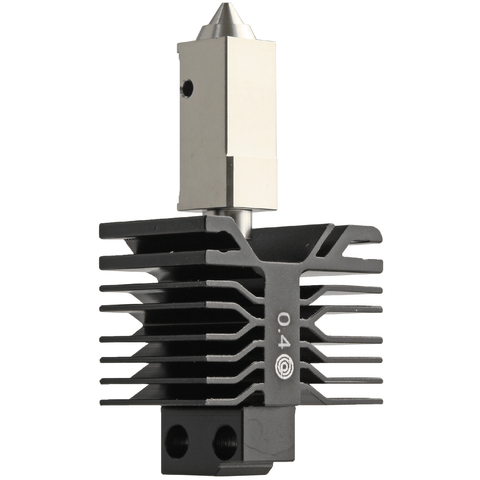

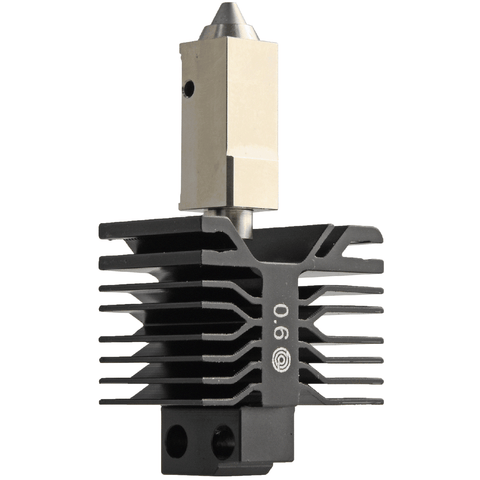

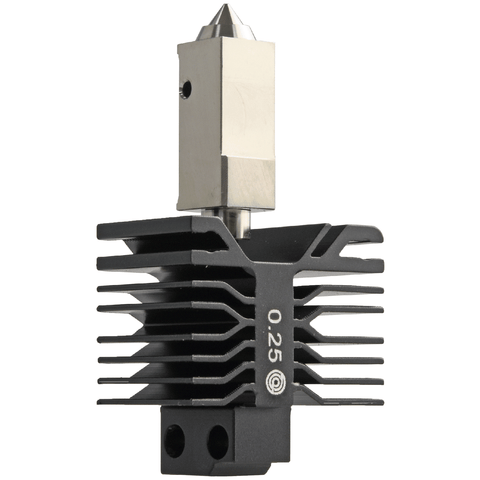

Nozzle diameter overview

0.2 mm: highest detail fidelity, slower prints.

0.4 mm: standard size, optimal balance of detail and speed.

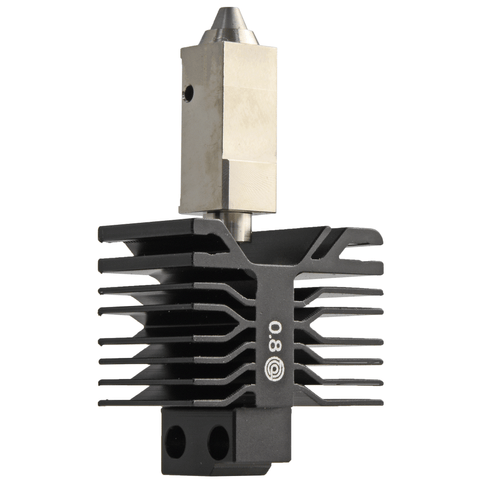

0.6–0.8 mm: faster printing, more stable parts, less risk of clogging.

1.0 mm and larger: maximum speed and robust parts, especially with high-flow hotends.

Practical tips for the right choice

- Switch to hardened nozzles in time for abrasive filaments (CF, glow, wood).

- Use high-flow or CHT nozzles for wide lines and large parts.

- Keep spare nozzles in various sizes ready to stay flexible.

FAQ – Frequently asked questions about 3D printer nozzles

When should I change my nozzle?

If surfaces become rough, under-extrusion occurs, or filaments are not fed evenly, a nozzle change is usually due.

Which nozzle is best for PLA?

A 0.4 mm brass nozzle is standard. Those who want to print faster choose 0.6 mm.

Which nozzle for carbon or glass fiber filaments?

Only hardened steel or ruby nozzles, as brass nozzles would wear out quickly.

Conclusion: The right 3D printer nozzle saves time, improves quality, and extends the lifespan of your hardware. Choose the right size and material for your project now.